Battery protection is key in electronics, especially for rechargeable systems like lithium-ion batteries. DIY Battery Protection lets professionals and hobbyists improve their projects. They can create custom battery management systems. This guide will show you how to use transistors to make your battery systems safe and long-lasting.

It covers the Battery Management System in detail. You’ll learn about voltage regulation, current limits, and temperature control. We’ll use reliable components like the IRLML6401 MOSFET.

It’s important to understand how battery protection works. For example, NiMH batteries are safe between 0.8V and 1V. A good circuit design will stop at about 1.8V to avoid deep discharge. The IRLML6401 has a low on-resistance of 0.125 Ohms, making it great for up to 500mA currents.

Adding a red LED for voltage reference and a T2 NPN transistor helps. They allow for quick switching to prevent overheating.

Key Takeaways

- Battery protection is vital for the longevity of lithium-ion systems.

- Effective circuits aim to cut off discharge levels at approximately 1.8V.

- The IRLML6401 MOSFET is an excellent choice due to its low on-resistance.

- Utilizing a red LED can provide an accurate voltage reference for the circuit.

- Fast switching with transistors can help mitigate overheating in circuits.

- Cost-effective and efficient DIY battery management systems are achievable.

Introduction to DIY Battery Protection

Understanding battery protection is key when making a reliable battery system. Battery Protection stops problems like overcharging and too much heat. This is especially important for those making DIY Battery Pack Design.

Using good protection circuits can make batteries last longer and work better.

Importance of Battery Protection

Battery protection is very important. Lithium-ion batteries are common but can be dangerous if not charged right. They might swell or even explode if not charged safely.

Adding safety features to battery designs helps them last longer and keeps users safe. Battery Management Systems (BMS) are crucial. They watch charge levels and balance charging to prevent overcharge.

Overview of Transistor Role

Transistors are essential in battery protection circuits. They act as switches to disconnect batteries when there’s a problem. This keeps things safe.

The Transistor Role also includes controlling current and voltage. This makes sure batteries work well. By using transistors in DIY projects, people can make safer and more efficient batteries. For a step-by-step guide, check out this DIY Battery Protection project.

Understanding Battery Chemistry

Learning about battery chemistry is key for managing batteries well. This is true for different types like lithium-ion, nickel-cadmium, and lead-acid. Each type has its own traits that shape how they’re made and used.

Types of Batteries

Various batteries are crucial for many electronic devices. The main ones are:

- Lithium-ion: These batteries are known for their high energy and long life. They’re often found in portable gadgets and electric cars.

- Nickel-cadmium (NiCd): Used in power tools, these batteries need air because they release gases over time.

- Lead-acid: Common in cars, these batteries are strong but can be heavy and big.

Knowing about these batteries helps in making the right protection circuits. For example, lithium-ion batteries need protection against overcharging and low voltage to avoid damage.

Battery Voltage and Current Concepts

Understanding voltage and current is crucial for battery protection. Important terms include:

- Nominal Voltage: The usual voltage a cell gives out when it’s being used.

- Charging Voltage: The voltage needed to charge the battery, which affects its life.

- Current Ratings: These show the max current a battery can handle without getting damaged.

For instance, lithium-ion batteries have a 3.6V nominal voltage. Lead acid batteries work at 2.0V per cell. Keeping an eye on these voltages is important for safe battery use, especially in demanding situations. More on reliable overcurrent protection circuits can be found here.

Basics of Transistors

Transistors are key in electronics, acting as switches or amplifiers. Knowing the basics of transistors is crucial for designing circuits. They come in different types, each suited for specific tasks like managing batteries or controlling LEDs.

What is a Transistor?

A transistor is a semiconductor device that controls electrical signals. It works by using a small current at the base to control a larger current. This makes transistors great for switching or amplifying signals in circuits.

Types of Transistors for Battery Protection

There are several types of transistors good for protecting batteries. These include:

- Bipolar Junction Transistors (BJT): NPN and PNP types like 2N3904 and 2N3906 are great for DIY projects. They work well with resistors from 100-100kΩ.

- Field Effect Transistors (FET): Power MOSFETs are often used in series with battery packs. It’s important to choose FETs with low forward voltage drop, like Schottky diodes.

- Relay Alternatives: Relays can also be used for battery management. They offer low contact resistance and are efficient.

For more information on designing Transistor-Based Battery Protection Circuits, check out this comprehensive guide. It provides detailed steps for building circuits for your project.

| Transistor Type | Common Models | Max Collector Current | Applications |

|---|---|---|---|

| BJT | 2N3904, 2N3906 | 200mA (recommend 100mA) | LED control, microphone amplification, similar low-power tasks |

| FET | Power MOSFET | Varies; larger types can handle higher loads | Battery protection, motor control, high-current applications |

| Relay | Latching Relay | Varies based on design | Battery management, switching circuits |

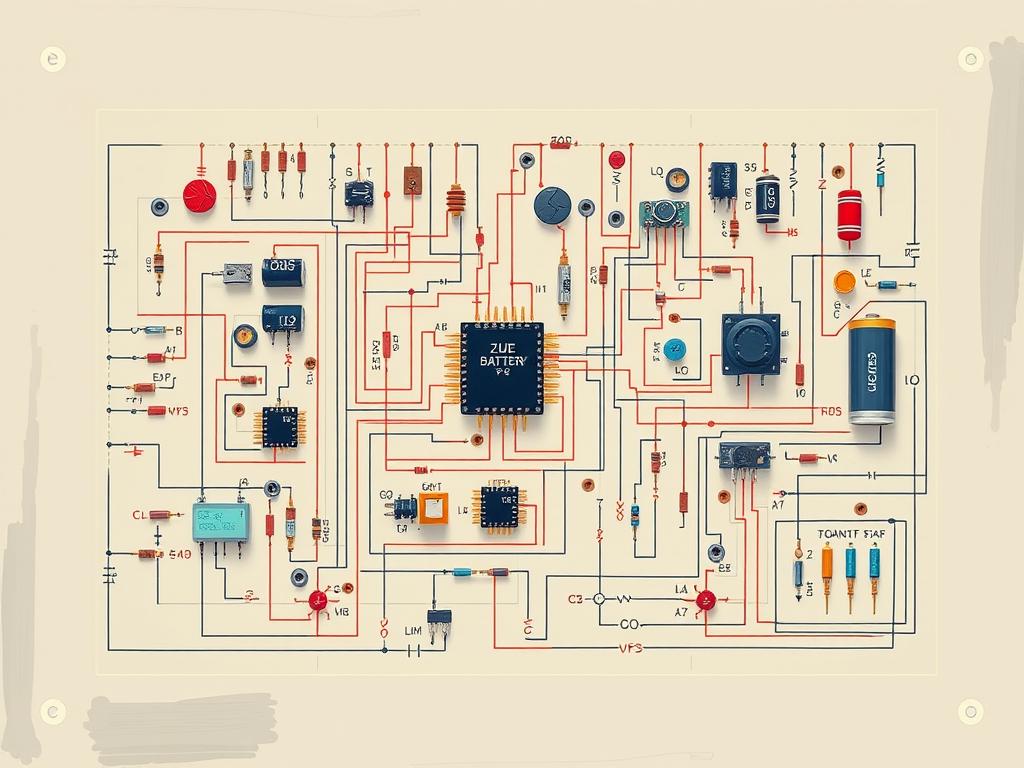

Circuit Design Principles

Creating a good battery protection circuit needs a deep understanding of Circuit Design Principles. Each part must be chosen carefully and placed right in the design. This makes a plan that shows how current flows and where problems might happen, especially in Battery Protection Circuit Design. Taking a detailed approach can really improve how well it works and how long it lasts.

Key Considerations in Circuit Design

When making a battery protection circuit, there are a few important things to think about. These include:

- Protection Against Short Circuits: Putting in safety measures to stop damage from sudden short circuits.

- Load Current Management: Making sure the current load is safe to keep the battery going longer.

- Component Specifications: Picking parts based on their electrical traits to make sure they work well together.

- Thermal Management: Handling heat by how parts are laid out and how they cool down.

Understanding Schematic Diagrams

Schematic diagrams are key in showing how parts work together in a battery protection circuit. They act as maps, making it easier to see connections and what each part does. A good diagram should have:

| Component | Function |

|---|---|

| Resistors | Control current and split voltage in the circuit. |

| MOSFETs | Work as switches to control current and protect against too much current. |

| ICs | Have functions for watching and protecting, making sure it’s safe to use. |

| Capacitors | Keep voltage steady and clean out power supply noise. |

Using good Schematic Diagrams and Circuit Design Principles helps make better battery protection systems. For more on simulating and charging, check out the Battery Protection Circuit Design guide. This way, you make sure your design works well and is safe to use.

Creating an Effective Protection Circuit

Designing a reliable protection circuit is key for rechargeable batteries to last long and work well. Different Protection Circuit Methods can greatly improve battery safety and performance. It’s important to address Overvoltage Protection and Undervoltage Protection to keep the battery in good shape.

Common Protection Methods

Battery protection involves using special integrated circuits (ICs) to watch over charging and discharging. For example, the DW01 chip paired with 8205A transistors works well. This combo helps prevent damage by disconnecting the battery when needed.

Designing for Overvoltage and Undervoltage Protection

Overvoltage Protection is crucial during charging to keep voltage within safe levels. This is done by constant monitoring and setting limits. Undervoltage Protection stops the battery from discharging too low, which could harm it. The circuit must disconnect the battery when it gets too low.

For more on picking the right transistors for protection, check out choosing the right transistor package.

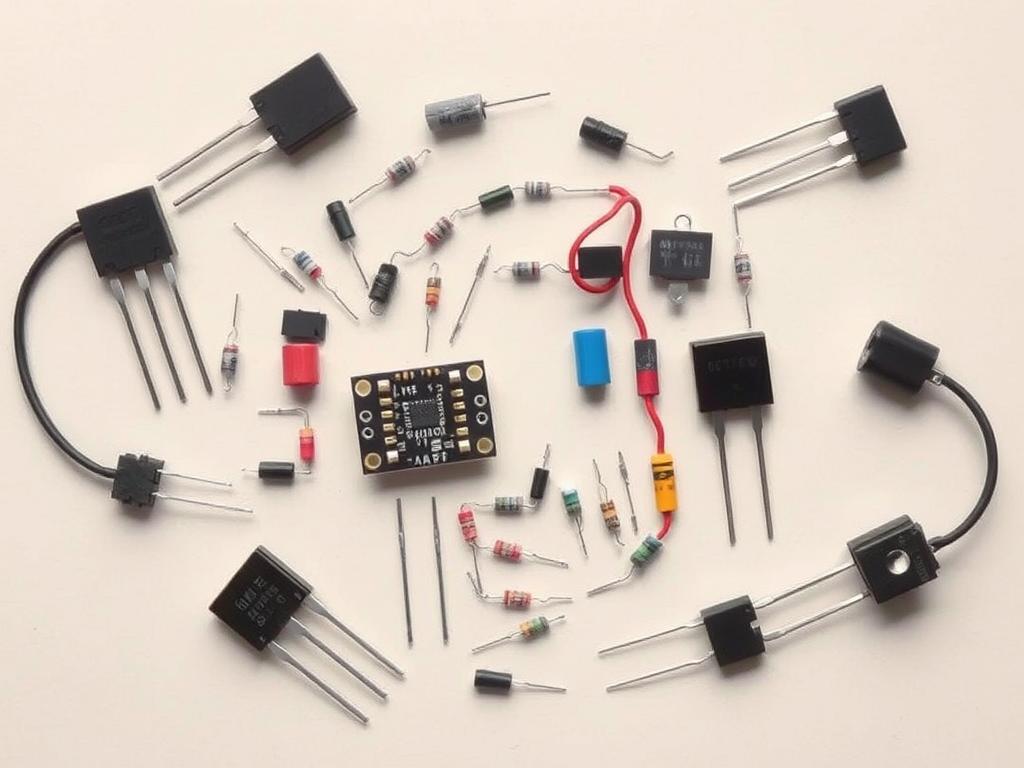

Components Needed for Your Project

Building a reliable battery protection circuit needs the right parts. Choosing the right components is key for a long-lasting and safe project. This part talks about the must-haves, including battery management system parts and top brands for quality.

Essential Components List

To make a good battery protection circuit, you need these parts:

- Battery Charger IC (e.g., LP4060 for lithium-ion batteries)

- Microcontroller (e.g., XIAO ESP32C3 for remote monitoring)

- Protection ICs (like the DW01 for safety features)

- Transistors for switching tasks and control

- MOSFETs for precise dissipation of electrical energy

- Various resistors and connectors

Using these components for battery protection helps avoid overcharging or overheating. This is crucial for DIY projects, RC models, and solar power setups.

Recommended Brands and Sources

For top-notch components, quality matters. Here are some trusted sources:

| Component Type | Brand | Recommended Source |

|---|---|---|

| Battery Charger IC | Texas Instruments | Various Electronics Retailers |

| Microcontroller | Seeed Studio | Amazon |

| Protection IC | Silicon Labs | AliExpress |

| MOSFETs | ON Semiconductor | Digikey |

When picking battery management system components, go for well-known suppliers. This ensures your circuit works well and lasts long.

Steps to Build Your Protection Circuit

Building a protection circuit needs focus and careful steps. It helps avoid problems like overcharging and short circuits. A clear plan makes it easier, especially for newbies. This guide will show you a Step-by-Step Battery Protection way to build your circuit.

Step-by-Step Guide

- Gather Materials: Get all parts needed, like a PIC, MOSFET, power resistor, and an optoisolator. A small pack of 3-10 Ah capacity costs about $3.25.

- Plan Your Schematic: Make a layout for your circuit. Focus on the right connections between parts for it to work well.

- Assembly: Solder connections as shown in your layout. Make sure all parts are fixed right.

- Integrate Protective Measures: Add parts to protect against too much voltage and too little voltage. This makes your circuit safer and more reliable.

Tips for Beginners

- Begin with simple designs before tackling harder ones.

- Use good guides and tutorials to learn more about it.

- Try soft circuit electronics for more design freedom.

- Be careful with high voltage parts; safety first.

Testing Your Protection Circuit

It’s crucial to check if a protection circuit works well. This ensures it performs reliably and safely. Experts use different methods to test how the circuit acts under different situations.

Methods for Testing Circuit Functionality

There are several ways to test a Battery Protection Circuit:

- Use a digital multimeter to check voltage and current.

- Simulate faults to see if the circuit disconnects correctly.

- Introduce noise, like from a buzzer, to test how it handles sudden changes.

- Do load dump tests to see how it handles sudden changes in conditions.

For example, the Arduino Nano 33 BLE can handle up to 21V. So, it’s important to test protectors on circuits that might go over this. You can use special components like the TP6KE18A diode to protect against high voltages.

Troubleshooting Common Issues

When fixing circuit problems, common issues include wrong wiring, bad connections, or worn-out parts. Here’s how to troubleshoot:

- Look at the solder joints and connections to make sure they’re good.

- Check for overheating and unusual signals with an oscilloscope.

- Measure resistance values to spot any problems.

- Make sure protection diodes and transistors work right.

Adding extra components for connectors can help protect the circuit. Following AEC standards is important when designing and testing circuits for cars.

| Testing Method | Description | Key Components |

|---|---|---|

| Digital Multimeter | Measures voltage and current across the circuit. | Multimeter |

| Noise Simulation | Checks transient response by introducing noise. | Buzzer |

| Load Dump Simulation | Simulates sudden surges to test circuit stability. | Capacitors, Resistors |

| Oscilloscope Measurement | Analyzes voltage spikes to ensure voltage is within acceptable limits. | Oscilloscope |

Safety Precautions When Working with Batteries

Working with batteries needs careful safety steps to avoid accidents and damage. Following the right Battery Safety Guidelines is key for personal safety and protecting your gear. Knowing how to handle different battery types, like Li-ion and LiPo, is crucial for safety.

General Safety Guidelines

Before starting any battery task, it’s vital to follow important Safety Precautions. These include:

- Wear the right protective gear, like gloves and eye protection.

- Make sure the work area is free from flammable stuff.

- Be careful to avoid short circuits by managing connections well.

- Charge batteries within their safe voltage limits.

- Check batteries for damage often and replace them when needed.

Handling Li-ion and LiPo Batteries

Li-ion batteries need extra care because they can get damaged by overcharging and overheating. Important steps include:

- Keep an eye on cell voltage to not go over 4.2 V.

- For projects with multiple Li-ion batteries, like two in series for 8.4 V, use protective circuits.

- Use zener diodes to stop overcharging and back current protection with diodes.

- Make sure batteries stay in a safe temperature range, between 10°C and 25°C, for best performance and life.

- Turn off loads automatically when voltage gets low to prevent damage.

For more detailed guidelines and tips on choosing components for battery projects, including transistors, check this resource. Following these safety steps will lower accident risks and improve your battery system’s performance.

Advanced Features to Enhance Protection

Adding advanced features to battery protection systems makes them safer and more efficient. Fuses and Breakers, along with Smart Battery Management Systems, are key. They help users keep an eye on, control, and protect battery systems well.

Incorporating Fuses and Breakers

Fuses and breakers are vital for safety. They stop the flow of electricity when it gets too high. This prevents damage to the battery and connected devices.

When picking Fuses and Breakers, think about a few things:

- Current Rating: Make sure the fuse can handle the maximum load. This prevents it from blowing too often but still protects well.

- Type: Choose fast-acting fuses for quick shutdown or time-delay ones for brief surges.

- Voltage Rating: Pick one that matches the battery’s voltage for safe operation.

Adding these devices to your circuit makes your battery system safer and more reliable.

Using Smart Battery Management Systems

Smart Battery Management Systems are crucial for keeping an eye on battery health. They offer real-time data and diagnostics. This lets users make smart choices.

- Temperature Monitoring: Keeps the system cool to avoid overheating.

- State of Charge (SoC) Monitoring: Shows how full or empty the battery is. This prevents overcharging or deep discharging.

- Cell Balancing: Makes sure all battery cells charge and discharge equally. This extends their life and improves performance.

Recommended models for Smart Battery Management include Daly BMS, Ant BMS, and Chargery BMS. They offer different control options for various needs.

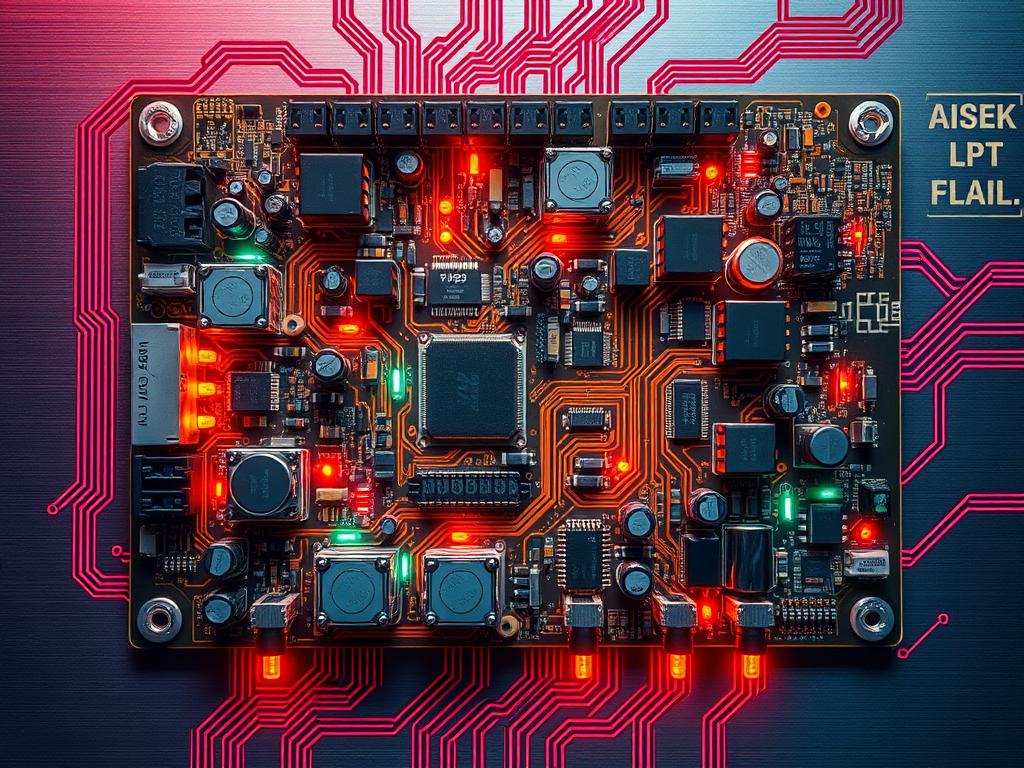

Real-Life Applications of DIY Battery Protection

DIY battery protection circuits are key for better performance and safety in many electronic systems. They are used in everyday projects and help with renewable energy. Knowing how they work and how to use them can make devices last longer and work better.

Examples in DIY Electronics Projects

In electronics projects, DIY battery protection helps keep devices safe from harm. For example, in hobbyist circuits, a basic battery management system (BMS) stops overcurrent issues. It does this by turning on discharge MOSFETs automatically.

A typical BMS uses a microcontroller (MCU) to manage charge and discharge. MOSFETs’ internal body diodes let current flow when needed. This is crucial in many projects, like:

- Arduino-based gadgets

- RC cars and drones

- Wearable technology

- Custom LED lighting systems

These projects show how important MOSFET drivers are for control and safety. Designers often improve their designs to keep devices safe and efficient. They make sure their designs follow safe operating areas, as explained in this article.

Benefits in Renewable Energy Systems

Renewable energy systems, like solar and wind power, also benefit from DIY battery protection. These systems need good battery management to last long and work well. Smart battery management stops batteries from getting too low, like below 10.8V, which can damage them.

By using DIY battery protection, users can:

- Keep an eye on battery health all the time

- Charge and discharge safely

- Disconnect automatically in extreme cases

- Reduce power loss from low voltage

This approach brings big renewable energy benefits. It helps power systems work well even when conditions change. With careful design and the right components, like Schottky diodes, DIY fans can make strong energy systems that last.

In summary, DIY battery protection is crucial for both personal electronics and renewable energy projects. It makes devices work better and last longer. Knowing how each part works and designing circuits well is key to success.

Future of Battery Protection Technology

The evolution of battery protection technology is key for better safety and performance. New materials and monitoring systems are changing battery management. These changes aim to make batteries in consumer electronics safer and last longer.

Innovations in Battery Safety

New Battery Safety Technology includes smart circuit designs and advanced management systems. For example, each circuit in DIY battery projects has a 25A max blade fuse. They also support remote control for up to six circuits, each with a 31A max current sensor.

Chargers like the TP4056 LiIon charger IC charge batteries efficiently at up to 1 A. These chargers are affordable and easy to find on platforms like Aliexpress.

Designs can be adjusted for different cell capacities using the TP4056. This makes batteries safer and reduces the risk of failure.

Potential Impact on Consumer Electronics

The impact of these advancements on consumer electronics is huge. Safer batteries mean more reliable devices, which makes users happier. Designs with switching regulators, like the PAM2306, handle high currents efficiently.

These devices power innovations like the Raspberry Pi Zero. This makes battery packs work better and more efficiently.

| Feature | Specification |

|---|---|

| Max Blade Fuse | 25A |

| Current Sensor per Circuit | 31A |

| Minimum Input Voltage (Vinmin) | 14V |

| Maximum Input Voltage (Vinmax) | 36V |

| Max Current Rating (Imax) | 30A |

| Typical Quiescent Current | |

| Voltage Divider Max Output | 1.20V |

Innovations show that battery protection technology is getting safer and better. As systems like this DIY battery management system improve, we look forward to a safer battery-powered future. For more on DIY battery management systems, check out here.

Conclusion

Building a DIY battery protection system with transistors is key for electronics fans. It makes batteries safer and more efficient. By following good design rules and adding protection, DIYers help improve battery tech.

Components like transistors and supervisory ICs are crucial. They help batteries work well and protect against damage from too much or too little power.

Key Points Recap

Important parts like the TP4056 charger module and zener diodes are vital. They help control battery use. The specs show how careful design is important.

These details lead to better battery protection. This means batteries last longer and work well in many situations.

Encouragement for DIY Enthusiasts

DIY fans should learn more about using transistors and other parts. This knowledge can lead to new battery management ideas. Check out this guide on high-frequency transistors for more info.

By exploring these areas, DIYers can help create new tech. They also make electrical work safer.