Making a simple motor speed controller is key for both hobbyists and professionals. This guide shows how to build a motor speed control circuit using transistors. It covers the tools, methods, and uses of such a controller.

A good motor speed controller lets you control motor speed precisely. This is useful in many areas, from DIY projects to big industrial machines. You’ll learn how transistors are crucial in making these circuits work well.

Key Takeaways

- Transistor choice is critical; the 2N2222 is recommended for simplicity.

- Adding a 10k resistor prevents open circuit issues on the Arduino.

- A flyback diode is essential for protecting against back EMF.

- Common ground between Arduino and battery prevents circuit failures.

- Clear circuit diagrams enhance trouble identification and circuit analysis.

- The circuit can drive multiple motors by duplicating the setup.

Introduction to Motor Speed Controllers

Motor speed controllers are key for controlling electric motor speed. They adjust voltage to let motors run at different speeds. This makes them useful for many tasks.

What is a Motor Speed Controller?

A motor speed controller changes an electric motor’s speed by adjusting power. It uses parts like transistors or MOSFETs. For example, the IRFZ24N MOSFET is great for handling high voltage and current.

This is because it has a low drain-source ON resistance. It’s better for tasks needing more power than simpler parts like the 555 timer.

Importance of Speed Control in Motors

Speed control is vital in many fields. It helps motors run smoothly and efficiently. For instance, in DC motors, controlling current affects speed.

More back electromotive force (emf) and changed current dynamics mean better performance and less energy use.

Adding flyback diodes, like the 1N4007, protects the circuit from spikes. This keeps the motor reliable under changing loads. High-speed universal motors also benefit from better speed control, showing its value.

Understanding Transistors in Circuit Design

Transistors are key in making electronic circuits work, especially in motor controllers. They help boost and switch electrical signals. Knowing how to use them is crucial for modern electronics.

What are Transistors?

Transistors are devices that can amplify or switch signals. They have three layers of semiconductor material. This makes them essential for controlling motor speeds.

Types of Transistors Used in Speed Controllers

Several types of transistors are used in motor control:

- NPN Transistors: These are the most common and preferred for motor control. They have high current gains and are used for switching or amplification.

- PNP Transistors: Less common, but used when NPN transistors are not enough.

- MOSFETs: Known for low power use and efficiency. MOSFETs like the IRF540N are great for high current needs.

Here’s a quick comparison of common transistors used in speed controllers:

| Transistor Type | Common Use | Advantages | Typical Current Rating |

|---|---|---|---|

| NPN | Amplification, Switching | High gain, reliable | 0.8A |

| PNP | Complementary switching | Effective for specific circuits | 0.5A |

| MOSFET | High-current applications | Low power loss, efficient | Depends on specific model |

Transistors are used in many circuits to control and amplify signals. Knowing their types and uses is key for making efficient motor controllers.

Components Needed for Building a Speed Controller

To make a good speed controller, you need the right parts. A basic list includes key elements that work together. They help manage motor speed well. Engineers and hobbyists often try different setups to save money.

Essential Components Overview

The table below shows the main parts for a basic motor speed controller. It lists how many you need and what they do:

| Component | Quantity | Function |

|---|---|---|

| NE 555 Timer IC | 1 | Generates PWM signals for speed control |

| LM358 Dual OPAMP IC | 1 | Amplifies the control signal |

| IR3205 N Channel MOSFET | 2 | Acts as a switch for power control |

| BC547 Transistor | 1 | Signals the MOSFET |

| LM317 Adjustable Voltage Regulator | 1 | Regulates voltage for adjustable outputs |

| AMS1117 5.0V Regulator | 1 | Provides stable voltage supply |

| 1N4148 Diode | 1 | Prevents voltage spikes |

| Capacitors (non-polar) | 3 (2 x 0.1uF, 1 x 0.01uF) | Filters and stabilizes signals |

| Resistors | 9 (3 x 1K, 3 x 10K, 1 x 4.7K, 2 x 100 ohm) | Sets gain and limits current |

| Preset Potentiometers | 3 (1 x 10K, 1 x 20K, 1 x 100K) | Adjusts variable parameters in the circuit |

| IC Bases | 2 (8 pin) | Supports easy integration and replacement of ICs |

Optional Components for Enhanced Functionality

Adding extra parts can make your speed controller better. It can do more things.

- Microcontrollers like Arduino can give you more control over the motor.

- Photoresistors and phototransistors can make the speed change with light.

- Using a comparator circuit can make the control more precise. It does this without making the circuit too complicated.

Together, these parts help control the motor’s speed well. For more on PWM circuits, check out this resource.

Circuit Design Basics

Creating effective motor control circuits starts with understanding basic parts and layout rules. Knowing how circuit diagrams work is key. It helps in making and fixing designs.

Understanding Circuit Diagrams

Circuit diagrams are like blueprints for motor speed controllers. They show how components connect. It’s important to know how to read these diagrams well.

These diagrams have important details like voltage and current limits. They also show how signals move. This info is crucial for designing motor control circuits.

Importance of Layout and Design

The way components are laid out affects a circuit’s performance. Following good layout rules helps avoid problems. It makes the circuit work better.

Good spacing and grounding are key. So is making connections in a logical order. This ensures the circuit works well. For more tips, check out guides on building transistor radios.

Building the Simple Motor Speed Controller

Building a simple motor speed controller needs careful assembly. You must follow a structured approach for a working DIY motor speed regulator. Using a breadboard for prototyping helps, especially when trying out different circuit setups.

Step-by-Step Assembly Instructions

To build a motor controller step by step, follow these steps:

- Gather all the parts listed in the parts inventory.

- Set up the prototype circuit on a breadboard for easy changes.

- Stick to the circuit diagram to make sure connections are right.

- Add a basic PWM signal from a microcontroller for speed control.

Tips for Efficient Assembly

For the best results in assembling your motor speed controller, keep these tips in mind:

- Make sure all connections are tight to avoid electrical shorts.

- Keep wiring organized to avoid confusion and make troubleshooting easier.

- Place components correctly for good heat dissipation and function.

Knowing the parts used in this build, especially specialty transistors, can really improve performance. For more info, check out this resource on specialty transistors. These parts are key for advanced features like efficient signal processing and power control, important in today’s electronics.

Wiring the Transistor

Getting the wiring right is key for transistors to work well in motor speed controllers. Knowing how to wire them right can make your circuits more reliable and efficient. It’s important to know how to wire different types of transistors, like the TIP120 or the IRF520.

Identifying the Transistor Leads

Transistors have three leads that need to be correctly identified:

- Bipolar Transistors: Base, Collector, Emitter

- MOSFETs: Gate, Drain, Source

Each lead has a specific role in how the transistor works. For example, the TIP120 needs a 1 kilohm resistor to limit current. MOSFETs need precise voltage to work right.

Proper Wiring Techniques

Using the right wiring methods can avoid problems like shorts and failures. For example:

- Using 22AWG solid core hookup wires makes connections strong.

- A 1N400x power diode protects against back voltage.

- Color-coded wires make setup easier and troubleshooting simpler.

Having a schematic drawing helps during assembly. It ensures connections are correct and helps spot wiring mistakes.

| Transistor Type | Leads | Common Applications |

|---|---|---|

| Bipolar (TIP120) | Base, Collector, Emitter | Current amplification, switching |

| MOSFET (IRF520) | Gate, Drain, Source | High-speed switching, voltage control |

Knowing how to identify transistor leads and wire them properly is crucial for a successful motor speed controller project.

Selecting the Right Motor

Choosing the right motor is key for controlling speed effectively. Knowing the different types helps meet performance goals. Brushed DC motors are popular for their simplicity and easy integration with speed controllers. Stepper motors are great for precise positioning.

Each motor type has its own strengths and weaknesses. They depend on what your project needs.

Types of Motors Suitable for Speed Control

- Brushed DC Motors: Ideal for brushed DC motor speed regulation. Easily controlled with PWM techniques and provide smooth speed variations.

- Stepper Motors: Great for applications requiring accurate positioning and control over speed. They operate with step inputs for in-depth control.

- Brushless DC Motors: Offers increased efficiency and lower maintenance requirements, along with smooth operation and longevity.

Factors to Consider When Choosing a Motor

When picking motors for speed controllers, consider a few key factors:

| Factor | Description |

|---|---|

| Voltage and Current Ratings | Make sure the motor’s voltage and current match the power supply for safe use. |

| Application Requirements | Think about the needed torque and speed for your application. It greatly affects your motor choice. |

| Compatibility with Controller Circuit | Check if the motor works well with your circuit design. This includes transistor types and control methods. |

By considering these factors, you can ensure a successful project. It will match your motor selection with your goals. For more on reliable overcurrent protection, check out these resources.

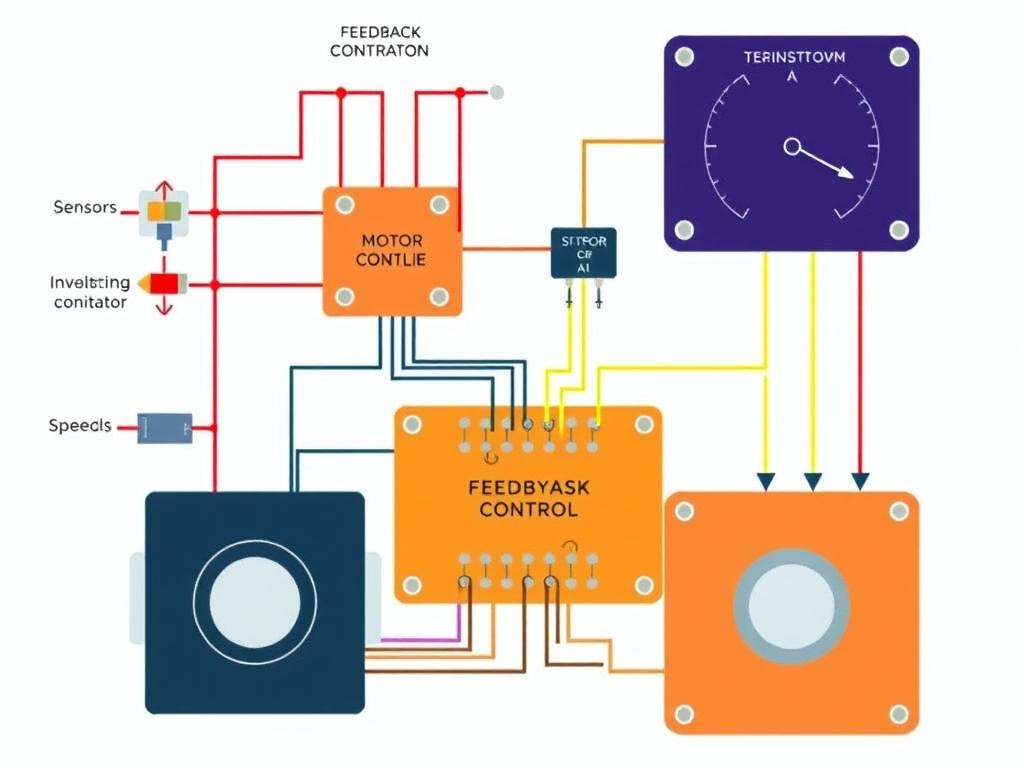

Integrating Feedback Systems

Feedback systems are key to improving motor speed control. They let us keep an eye on the motor’s work. This way, we can tweak it in real-time to match its speed and position. Good feedback systems make motors more precise and quick, which is vital in many fields.

What is Feedback in Motor Control?

Feedback in motor control means using the motor’s performance data to adjust its work. This lets us fix any issues right away. It helps the motor stay on track, making it more efficient.

Types of Feedback Systems

There are a few main types of feedback systems for motor speed control:

- Closed-loop Systems: These use sensors to check the motor’s speed and position. They adjust automatically for better accuracy.

- Open-loop Systems: These don’t use feedback and just follow set rules. They’re good for simple tasks where exactness isn’t as important.

- PID Controllers: These are used in closed-loop systems. They use different control methods to fine-tune the motor’s speed.

Using a good feedback system, like one with 48 counts per revolution, helps control the motor better. For example, it helps adjust the motor through PWM signals. This makes the motor respond faster and reduces errors.

For more on choosing the right parts for motor control, check out this guide. It talks about the importance of knowing what you need and how it works.

| Feedback System Type | Key Characteristics | Applications |

|---|---|---|

| Closed-loop | Real-time data adjustment, high accuracy | Robotics, automated manufacturing |

| Open-loop | No feedback, predetermined output | Simple control applications |

| PID Controller | Combines proportional, integral, and derivative actions | Precision speed control in dynamic systems |

Feedback control systems are key to making motors work well. They help the motor stay on track, improving its performance.

Testing Your Speed Controller

Testing your motor speed controller is key to its reliable performance. Before you start, make sure to follow safety steps. This helps avoid risks when working with electrical parts. Always check that all connections are tight and wear the right protective gear.

Safety Precautions Before Testing

Knowing the safety rules is important to avoid risks when testing motor controllers. Here are some key steps:

- Check all wiring for damage and make sure connections are tight.

- Use insulated tools to avoid short circuits.

- Make sure the power supply’s voltage matches your circuit’s design.

Procedures for Testing Functionality

After taking the necessary safety steps, start testing. Here’s how:

- Turn on the circuit and watch the current to avoid overloads.

- Verify the PWM signal outputs at the right pins, like those connected to the MOSFET.

- Watch how the motor works to see if it’s adjusting speed right, making sure it’s running smoothly.

These steps help you test motor speed controller performance and ensure circuit functionality. For more detailed assembly instructions, check out the full guide at this detailed resource.

Troubleshooting Common Issues

When working with motor speed controllers, troubleshooting is key. It ensures they work well and reliably. Often, problems come from wiring mistakes. These can make the controller output constant voltage instead of changing it.

These issues can usually be fixed by carefully checking the wiring against the circuit diagram.

Identifying and Fixing Wiring Problems

First, look for wiring problems in motor controllers. Wrong wiring can make the motor run wrong or even damage it. Use a multimeter to check if connections are good.

Make sure all parts are wired right. Pay close attention to the three diodes and two thyristors. They are key to controlling electricity flow.

If the machine always shows 110V DC, it means there’s a wiring or part problem. Check the phase angle control circuit and the zero-crossing detector carefully. This careful check can stop big problems.

Understanding Transistor Failure Modes

Transistors can also cause big problems in motor controllers. The Darlington TIP122 transistor, for example, can fail from too much heat or stress. This is especially true when motors use a lot of current, like 0.8A for 12V motors.

Using good heat sinks is key when using transistors like the TIP122. They need only 2.5V at the base to work. Learning how to measure transistor capacitance can also help. Get tips from resources on transistor measurements to improve performance.

Enhancing Your Speed Controller

Improving a motor speed controller means adding better parts and new features. High-performance transistors and capacitive filters can make it work better. These upgrades help control motors more precisely and reliably.

Upgrading Performance with New Components

Choosing better transistors is a key upgrade. For example, the 2SC6097 transistor can handle up to 3A. It’s great for controlling motors because it has a low VCE(sat) of about 150mV.

This low value means less power loss and better efficiency. Adding these parts can really boost how well your speed controller works.

Adding Remote Control Features

Adding remote control makes motor speed controllers more useful. Using RF modules or Bluetooth lets you adjust motor speed from a distance. This makes things easier for users and helps systems work better together.

| Transistor Model | Beta Value | Max Current (A) | VCE(sat) (mV) |

|---|---|---|---|

| 2SC6097 | 20 | 3 | 150 |

| TIP122 | 100 | 5 | 200 |

By adding top-notch parts and remote control, users get better efficiency. This upgrade also makes motor systems perform better overall.

Applications of Simple Motor Speed Controllers

Simple motor speed controllers are key in many areas. They help meet different needs and use the latest technology. They work well in both big industrial settings and small hobby projects, showing their wide range of uses.

Industrial Uses of Speed Controllers

In big industries, speed controllers are crucial. They help control many devices. Here are some examples:

- Conveyor belts: Keeping the speed steady for moving materials.

- Fans: Adjusting fan speed for better airflow in systems.

- Pumps: Changing how fast fluids move in making and chemical work.

Choosing the right motor, like brushed or brushless DC motors, is important. Brushless DC motors are great because they’re efficient and need less upkeep. They’re perfect for precise work in big industries.

Hobby Projects Benefiting from Speed Control

In hobby projects, motor controllers let people get creative and learn. Some fun projects include:

- Robotics: Giving robots the exact control they need.

- Model vehicles: Making cars, boats, or planes run better with the right speed.

- CNC machines: Helping make detailed designs by moving parts accurately.

Using these controllers in projects makes things better and teaches about motor control. Working with brands like ASPINA and Integra Sources helps hobbyists get the right parts and support.

| Application | Typical Motors Used | Key Benefits |

|---|---|---|

| Conveyor Belts | Brushed and Brushless DC Motors | Consistent speed, reduced wear |

| Fans | Brushless DC Motors | Lower noise, high efficiency |

| Pumps | Brushed DC Motors | Cost-effectiveness, simplicity |

| Robotics | Stepper Motors | Precision control, fine-tuned movements |

| Model Vehicles | Brushed DC Motors | Enhanced performance, easier adjustments |

| CNC Machines | Stepper Motors | Accurate positioning, detailed designs |

Conclusion

Building a basic motor speed controller with transistors needs careful steps. You must pick the right parts and test them well. This way, you can make a DIY motor speed controller that works great in robotics and automation.

First, get all the parts you need. Then, design a circuit that makes sense. Finally, follow the steps to assemble and test it.

Summary of Steps

In this project, key parts like the Arduino Uno and BT151 SCRs are crucial. They help the motor work well. You might also want to add a PI controller or a feedback system from a bicycle dynamo.

For more on how to control motors better, check out this guide on PWM control techniques.

Final Thoughts on DIY Motor Speed Controllers

When making a DIY motor speed controller, focus on precise control and safety. Use snubber circuits and pulse transformers to avoid risks. As technology grows, so can your designs.

Exploring wireless control, multi-motor systems, and IoT integration is exciting. These projects not only teach you a lot but also lead to new ideas in motor control.