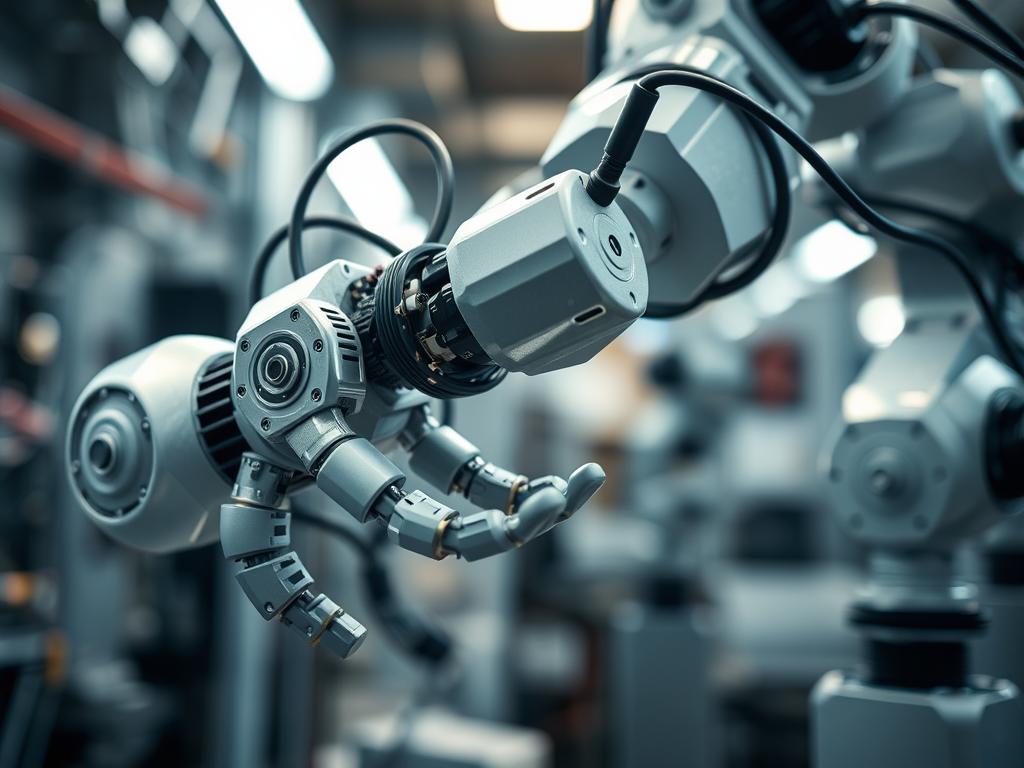

Industrial pick and place robots handle up to 200 products per minute with astounding precision. These robotic marvels transform production lines across various industries. Their speed, accuracy, and tireless work ethic are changing manufacturing processes.

Integrated servo motor and controller systems have revolutionized industrial automation. These components allow precise control over velocity, torque, and position. As a result, manufacturing efficiency has soared, with robots working non-stop.

Robotic technology focuses on smart, safe production. In high-risk environments, robots replace human workers, enhancing safety while maintaining output. Machine vision technology enables robots to detect flaws with unprecedented accuracy.

Manufacturers using robotics report significant improvements in productivity, accuracy, and quality. This leads to a high return on investment. Industrial automation is becoming an attractive option for businesses of all sizes.

Pick and place industrial robots are shaping the future of manufacturing. They streamline assembly lines, reduce labor costs, and increase productivity. Integrated servo systems play a crucial role in driving this new industrial revolution.

Understanding Integrated Servo Motors and Controllers

Integrated servo systems are transforming motion control in industrial robotics. These compact units combine brushless DC motors and controllers. They offer high precision and efficiency in a single package.

What is an Integrated Servo System?

An integrated servo system combines a servo drive with a brushless DC motor. This design reduces wiring complexity and saves space. It’s perfect for compact robotic applications.

The system uses closed-loop feedback for precise control. This enhances performance in pick-and-place operations.

Key Components: Motors and Controllers Explained

The core of an integrated servo system is the brushless DC motor. These motors provide high torque density and efficiency. They’re crucial for industrial robotics.

The built-in controller manages the motion control system. It uses sophisticated algorithms to ensure smooth operation.

| Component | Function | Benefit |

|---|---|---|

| Brushless DC Motor | Generates motion | High efficiency, low maintenance |

| Servo Controller | Manages motion control | Precise positioning, speed control |

| Encoder | Provides position feedback | Enables closed-loop control |

| Power Electronics | Controls motor current | Optimizes performance and efficiency |

The integration of these components creates a compact, efficient motion control system. This design shines in manufacturing environments with limited space. It delivers precision where it matters most.

Advantages of Integrated Servo Motors in Robotics

Integrated servo motors are transforming robotics and industrial automation. These compact units combine motor, encoder, and drive. They streamline robotic systems and boost overall performance.

Precision and Accuracy in Operations

Integrated servo motors excel at high-precision positioning. They use digital control systems and high-resolution feedback. This allows robots to perform tasks with remarkable accuracy.

Such precision is vital in industries like electronics manufacturing. Even small errors can lead to product defects.

These motors boast high-torque density, enabling compact robot designs. This is crucial in tight manufacturing spaces. Performance remains uncompromised despite the smaller size.

Energy Efficiency: A Competitive Edge

Integrated servo motors save energy compared to traditional setups. They eliminate long cable runs, reducing power losses. This leads to lower costs and a smaller carbon footprint.

- Faster response times for improved productivity

- Superior torque control for smoother operation

- Real-time feedback integration for enhanced performance

MDX Integrated Servo Motors showcase these advantages. They offer a cost-effective, simple system design solution. These motors quickly adapt to various industrial automation needs.

From material handling to complex motion control, MDX motors meet diverse requirements. They feature multiple command interfaces and environmental ratings.

The Role of Pick and Place Robots in Modern Manufacturing

Pick and place robots are transforming production lines across industries. They excel at repetitive tasks with unmatched speed and precision. These robots are crucial for manufacturing process optimization.

Streamlining Assembly Lines

Robotic assembly systems are boosting production efficiency. High-speed pick and place robots can operate at over 150 cycles per minute. Some models have cycle times under 0.15 seconds, but cost $500,000 or more.

These robots handle items from tiny grains to shoebox-sized objects. Their payloads range from 1 to 10 kg. They can adapt to various tasks, including welding, painting, and material handling.

Reducing Labor Costs and Increasing Productivity

Manufacturers cut labor costs while boosting productivity by automating repetitive tasks. Pick and place robots work tirelessly without breaks. They also enhance workplace safety by handling hazardous materials.

“Robotic arms contribute to increased efficiency, productivity, and throughput on production lines due to their ability to work at high speeds without breaks.”

AI and machine learning have improved these robots’ capabilities. This is especially true for vision systems and object recognition. These advances allow for greater precision and adaptability in manufacturing processes.

Real-World Applications of Integrated Servo Motors

Integrated servo motors fuel innovation across industries. They power precision manufacturing and automated production. These systems excel in tasks requiring high accuracy and efficiency.

Automotive Industry: Precision in Assembly

Integrated servo motors revolutionize automotive assembly lines. Robotic arms with these motors place components with incredible precision. They ensure exact positioning of parts from tiny screws to complex electronics.

A major car maker saw a 30% boost in assembly efficiency with servo-driven robots. These systems handle windshield installation and engine assembly with unmatched accuracy. As a result, they reduce errors and improve overall vehicle quality.

Electronics Assembly: Miniaturization Mastery

The electronics industry relies heavily on integrated servo motors. Pick and place robots excel at handling delicate components. They position tiny parts with extreme accuracy, essential for creating modern, compact electronics.

A leading smartphone maker cut assembly time by 40% using servo-driven systems. These robots can place up to 120,000 components per hour. This speed far surpasses human capabilities, enabling faster production of advanced devices.

| Industry | Efficiency Gain | Key Benefit |

|---|---|---|

| Automotive | 30% | Improved assembly accuracy |

| Electronics | 40% | Faster component placement |

These examples show how integrated servo motors transform industrial robotics. They enhance precision and speed in manufacturing. As a result, they set new standards for production excellence.

Real-World Applications of Integrated Servo Motors

Integrated servo motors are transforming industrial robotics and precision manufacturing. These systems power automated production in many sectors. Their versatility and efficiency shine across various industries.

Case Study: Automotive Industry

In car manufacturing, servo-driven systems control robotic arms for assembly tasks. These tools excel at placing screws, fasteners, and electronic parts with high accuracy. As a result, production lines move faster and vehicle quality improves.

Case Study: Electronics Assembly

Electronics assembly depends on servo motors for complex tasks. Pick-and-place robots guided by these motors handle delicate components precisely. This technology is vital for making compact, modern devices like smartphones and tablets.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Component assembly | High precision, increased speed |

| Electronics | Circuit board production | Delicate handling, extreme accuracy |

Both industries use integrated servo motors to improve efficiency and product quality. These systems offer fast, accurate performance in manufacturing processes. Their impact on modern production is undeniable.

Challenges and Considerations in Implementing Servo Technology

Servo technology in manufacturing offers major benefits but presents automation challenges. Industries aiming for upgrades face hurdles in system integration and robotic implementation. These challenges require careful planning and execution.

Common Obstacles in Adoption

The initial cost is a significant challenge. Servo motors and controllers require substantial capital investment. Integrating new tech with existing systems can disrupt production.

Staff training adds complexity to the process. Maintenance and calibration are ongoing issues. Regular upkeep is crucial to maintain precision and prevent performance degradation.

Mitigating Risks and Maximizing Benefits

Manufacturers must plan carefully to overcome these hurdles. A thorough cost-benefit analysis is essential before system integration. Gradual implementation can ease transitions and reduce disruptions.

Proper training is key to success. Investing in employee education ensures smooth robotic implementation. This approach maximizes long-term advantages like increased efficiency and reduced operating costs.

| Challenge | Mitigation Strategy |

|---|---|

| High initial costs | Phased implementation |

| Integration difficulties | Comprehensive planning |

| Staff training | Ongoing education programs |

| Maintenance issues | Regular preventive checks |

Servo technology adoption in manufacturing continues to grow. The need for higher productivity and quality drives this trend. Improved servo motor designs offer energy-efficient systems with higher torque-to-inertia ratios.

Future Trends and Innovations in Servo Motors and Robotics

Servo motors and robotics are evolving rapidly, shaping smart manufacturing and Industry 4.0. Exciting developments are on the horizon. These promise to revolutionize automation and industrial processes.

Emerging Technologies to Watch

Servo motors are becoming more advanced. The global market could reach USD 1088.34 million by 2028. This growth stems from advances in materials, control algorithms, and sensors.

These improvements make servo motors more compact, faster, and precise. This opens up new possibilities in robotics innovation.

Machine learning algorithms are a notable trend. These smart systems analyze data from servo motors to predict maintenance needs. This reduces downtime and boosts operational efficiency.

The Impact of IoT and AI on Robotics

IoT and AI are changing robotics. IoT allows real-time monitoring of servo systems. AI enhances decision-making capabilities. Together, they create more flexible and connected manufacturing systems.

Energy efficiency is another key focus. Future servo motors will use less power while maintaining performance. This is due to advances in motor design and energy regeneration.

These improvements align with the growing focus on sustainable manufacturing in Industry 4.0.