Using transistors for motor speed control is efficient and cost-effective. This method simplifies the process, making it easier to control motors. It’s perfect for electronics projects, like PC fans or hobby projects.

The TIP120 transistor is a key component, handling up to 60 volts and 5 amps. It makes the design more accessible and reliable. You’ll also need a 1K resistor, 1N4004 diode, and a 1uF ceramic capacitor. These parts ensure the circuit works well and is safe.

For more on designing motor speed controllers, check out this resource.

Next, we’ll look into the technical details of using transistors for motor speed control. We’ll cover the essential configurations, advantages, and best practices for modern applications.

Key Takeaways

- Transistors provide an efficient means of motor speed control, enhancing performance.

- The TIP120 transistor serves as an intermediary for high-power devices.

- Key components, including resistors and diodes, play crucial roles in circuit design.

- PWM (Pulse Width Modulation) is vital for precise motor adjustments in electronic designs.

- Understanding component specifications helps prevent circuit malfunctions.

Understanding Motor Speed Control Techniques

Motor control techniques are key in many fields. They help control speed and torque precisely. Knowing the different motor types is crucial. Each motor type has its own traits that affect the choice of speed control methods.

This knowledge is vital for robotics, automation, and industrial uses.

Overview of Motor Types

There are many motor types, each with its own strengths and uses. The main types are:

- DC Motors: These motors can spin very fast, sometimes thousands of RPM. They are simple and efficient, making them great for changing speeds.

- Stepper Motors: These motors give precise control over speed and position. They are perfect for tasks needing high accuracy, like 3D printing and CNC machines.

- AC Motors: AC motors are often used in big industrial settings. They can handle more complex speed control methods because of their design.

Basic Principles of Speed Control

It’s important to know the basics of speed control. There are several methods used, including:

- Voltage Variation: Changing the voltage to the motor can control its speed.

- Pulse-Width Modulation (PWM): This method is good for DC and universal motors. It uses an 8-bit MCU to control the motor’s voltage and current, improving precision.

- Gear Systems: Gearhead motors can slow down the motor’s speed but increase its torque. For example, a 48:1 gear ratio does this.

Using advanced methods, like sensor technology in sinusoidal and vector control, boosts motor performance. These methods help choose the right motor control for specific needs.

The Role of Transistors in Motor Control

Transistors have changed the world of electronics since 1947. They are key for boosting and switching electrical signals. This is crucial for controlling motor speeds.

Their ability to control current and voltage helps engineers make motors work better. This leads to more efficient and effective motor control.

What Are Transistors?

Transistors are vital for handling electrical signals in today’s electronics. They are used for switching and amplifying. In motor control, they help adjust motor performance.

This makes motors work better and be more adaptable. Thanks to technology, transistors can switch very fast. They are used in many areas, like phones and fast networks.

Types of Transistors Used

Knowing the different types of transistors is key for choosing the right one for motor control. Here are the main types:

- Bipolar Junction Transistor (BJT): BJTs come in NPN and PNP types. They amplify signals and control current well.

- Field Effect Transistor (FET): FETs include IGBTs and MOSFETs. They use less power and are easy to make.

Choosing the right transistor type is important for motor systems. By using each transistor’s special features, engineers can make motors better. This ensures they work well and last long.

Advantages of Using Transistors for Speed Control

Transistors are key in modern speed control because of their many benefits. They improve efficiency and are cost-effective. This makes them a top choice for many in the electronics field.

Efficiency Improvements

Transistors boost efficiency in motor control systems. They switch quickly, reducing energy loss. This is vital for precise speed adjustments.

High-efficiency switching means devices work well under different loads. They waste less energy, leading to better performance and lower costs.

Cost-Effectiveness

Using transistors in motor control is often cheaper than old methods. They need fewer parts and fit easily into current systems. This saves money on materials and installation time.

This makes products more affordable. It helps meet the needs of a wide range of customers, making motor solutions cost-effective.

Key Components in Transistor-Based Motor Control Circuits

In motor control circuits, many parts are key to good performance and reliability. Knowing how resistors, capacitors, diodes, and inductors work helps make transistor-based systems better. Each part has its own job, making the circuit work well.

Resistors and Capacitors

Resistors control how much current flows, keeping transistors and other parts safe from too much current. They help set up how motor control circuits work. Capacitors smooth out voltage changes, which is vital for stable operation in changing speed and load situations. They keep the circuit running smoothly by storing energy.

Diodes and Inductors

Diodes stop reverse current, which could harm sensitive parts in motor control circuits. They let current flow one way but block it the other. Inductors store energy when current changes, helping keep power steady. This ensures transistors get the current they need to work well. Together, these parts make motor designs more advanced and effective.

Different Configurations for Transistor-Based Control

Knowing about different transistor setups is key for controlling motors well. The setup of transistors affects things like current, voltage, and how efficient they are in motors. The H-bridge and PWM setups are especially important for controlling speed and direction.

H-Bridge Configuration

The H-bridge setup is vital for controlling a motor’s direction. It changes the voltage to the motor to make it move forward or backward. This is crucial in things like robotics and electric cars.

The H-bridge uses four switches. These can be BJTs or MOSFETs. They help manage current and respond quickly to signals.

PWM (Pulse Width Modulation)

PWM controls the motor’s power by changing the pulse width. This method helps regulate speed and saves energy. By tweaking the PWM signal, engineers can adjust the motor’s speed precisely.

This approach also helps components last longer by reducing heat stress.

| Configuration Type | Application | Benefits |

|---|---|---|

| H-Bridge | Bi-directional motor control | Reversible motor direction, efficient control |

| PWM | Speed control | Reduced energy loss, precise speed regulation |

Transistor setups like the H-bridge and PWM offer special benefits for motor control. Understanding these setups helps in making better electronic designs and using them effectively in many areas.

Implementation: Building a Basic Motor Speed Control Circuit

Building a DIY motor speed control circuit needs careful planning and the right tools. Knowing what materials to use is key for making a circuit that works well.

Tools and Materials Needed

Here are the main parts you’ll need for a motor speed control circuit:

- Power Transistor (e.g., TIP120)

- Resistors

- Diodes

- Capacitors

- Microcontroller (e.g., Arduino)

- Connecting Wires

Each part has a special job. The power transistor controls the current and voltage. This lets you adjust the motor speed. A microcontroller, like Arduino, is key for changing the motor speed using PWM.

Step-by-Step Assembly

Assembling a motor control circuit needs focus. Here’s how to do it right:

- Get all your tools ready and make sure they work.

- Put the parts on a breadboard as shown in the schematic.

- Connect the power transistor to the microcontroller. Make sure the pins are right.

- Add resistors and diodes for safety and protection.

- Connect the motor to the transistor for speed control.

- Power up the circuit and test it with code on the microcontroller.

By following these steps, you can make a basic motor speed control circuit. It’s a great way to learn about building motor control circuits.

Troubleshooting Common Issues in Motor Control

Fixing motor control systems can be tough, especially when common problems pop up. Knowing how to spot these issues is key to keeping things running smoothly. Overheating, no motor response, and speed issues often point to wiring errors, bad parts, or power problems. A step-by-step approach to finding these problems can lead to good fixes.

Identifying Malfunctions

Several signs can show that a motor has problems, including:

- Overheating: This can happen if the motor is too loaded or can’t cool down well.

- Lack of motor response: This is often due to wrong connections or power issues.

- Erratic speed variations: This usually means there’s a problem with the control circuit parts.

Looking into wiring issues, like those found when fixing a lathe motor controller, can be very helpful. It’s important to check connections well and make sure all parts fit right before starting. For more tips on fixing motor problems, check out discussion forums.

Solutions for Common Problems

Fixing motor control issues needs a careful and detailed plan. Here are some steps to follow:

- Make sure all connections and wiring are correct.

- Check voltage at different points in the circuit to find where power is lost.

- Swap out any parts that might be broken, like resistors or capacitors.

- Use a special board for high current tasks instead of a breadboard for better reliability.

Also, making sure transistors and diodes are wired right is crucial to avoid problems. Switching to modern parts, like logic level MOSFETs, can also make things work better and more efficiently. For more on choosing the right components, see the guide on transistor packages.

| Problem | Possible Cause | Solution |

|---|---|---|

| Motor Overheats | Excessive Load | Reduce load or improve cooling |

| No Response | Incorrect Wiring | Check and correct connections |

| Speed Variation | Faulty Components | Replace or repair defective parts |

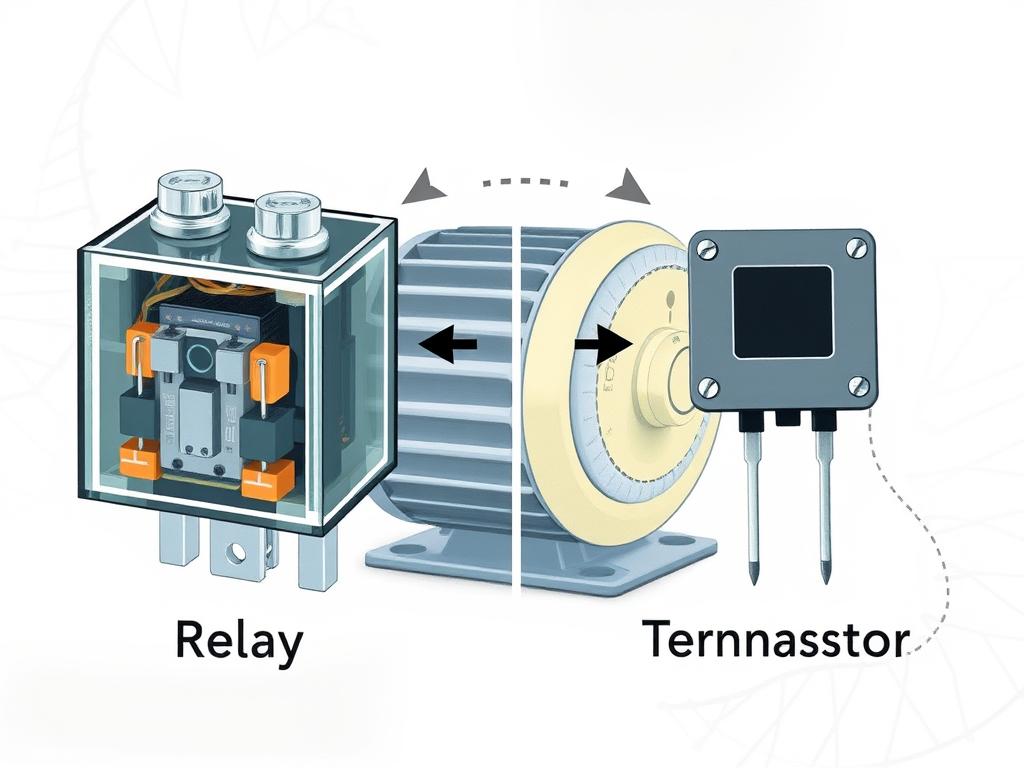

Comparing Transistors with Other Speed Control Methods

It’s important to know the differences between various speed control methods. This helps choose the best way to control electronic motors. When we look at relays and transistors, each has its own strengths and weaknesses. This comparison gives us a better understanding of how they work and their efficiency.

Relays vs. Transistors

Relays use mechanical control, which is good for simple tasks. Transistors, on the other hand, offer electronic control. This makes them faster and more efficient at handling signals.

When we compare relays vs. transistors, transistors win in speed and durability. Transistors like Insulated-Gate Transistors (IGTs) have low resistance when on. This makes them better for controlling speed in circuits.

Mechanical Speed Control vs. Electronic

Mechanical speed control is slow and less flexible. Electronic control, however, allows for precise adjustments through voltage or current changes. This makes electronic methods more reliable and efficient.

For example, PWM Chopper Control uses 8-bit MCUs for precise speed adjustments. This shows how electronic solutions improve efficiency and accuracy.

| Feature | Relays | Transistors |

|---|---|---|

| Control Type | Mechanical | Electronic |

| Response Time | Slower | Faster |

| Durability | Prone to wear | Long-lasting |

| Efficiency | Moderate | High |

| Input Voltage Control | Simple | Complex management possible |

Finding the right speed control method is key for electric motor performance. It affects durability and energy use. Moving to electronic control shows how technology meets modern needs.

For more on transistors, check out essential transistor terminology.

Case Studies: Successful Applications of Transistor Control

Transistor control has changed many fields, especially in industrial automation and robotics. It shows big wins from using transistor control systems. Looking at certain examples, we see the real benefits and progress made.

Industrial Automation

In industrial automation, moving to transistor-based motor controls has brought big gains. For example, variable speed Permanent Magnet (PM) motor drives are now used for conveyor belts and robotic arms. These systems make operations more flexible and save energy, which is key for cost savings.

Studies show how industries get smoother operations with high dynamic response and reliability of PM BLDC motors.

Robotics Applications

Robotics gets a big boost from transistor-based motor control, allowing for precise movements. Permanent Magnet DC Synchronous motors, or BLDC motors, show this with their speed and torque. This control lets robots do complex tasks better and use less energy.

Success in robotics shows the value of sensorless control. It makes designs simpler while keeping high performance. This progress boosts what robots can do and cuts down on maintenance needs, making them more useful in many areas.

Emerging Technologies in Motor Speed Control

The world of motor speed control is changing fast. New technologies like smart motor controllers and IoT in motor control are leading the way. These innovations make systems more efficient and smarter.

Smart Motor Controllers

Smart motor controllers are a big step forward. They use microcontrollers and sensors to make motors work better. They adjust to the environment in real-time for better performance.

These systems save energy and make motors last longer. They work with different types of motors, like BLDC and AC motors. This makes them useful in many places.

IoT Integration

IoT in motor control adds a new level of functionality. It lets users check motor performance from anywhere. This makes it easier to spot problems before they happen.

With IoT, maintenance can be done before it’s needed. This cuts down on downtime and keeps things running smoothly. Smart motor controllers and IoT together make things more efficient and reliable.

| Technology | Key Features | Benefits |

|---|---|---|

| Smart Motor Controllers | Microcontroller-based, sensor integration, dynamic adjustments | Enhanced efficiency, longer motor life, real-time adjustments |

| IoT Integration | Remote monitoring, data analytics, predictive maintenance | Reduced downtime, proactive management, improved decision-making |

Best Practices for Maintaining Motor Speed Control Systems

Keeping motor control systems in top shape is key to their performance and life span. By following the best practices, you can boost efficiency and cut down on failure risks. It’s important to regularly check and ensure safety in your maintenance routine.

Regular Checks and Balances

For effective motor speed control system maintenance, routine inspections are a must. By checking circuits and parts for wear, you can avoid sudden failures. Focus on these areas:

- Look for wear in wiring and connections.

- Check how control algorithms are working.

- Make sure power supply and grounding systems are stable.

For high-power motors, like a 75A motor, measuring stall current accurately is crucial. Using multimeters and Ohm’s law helps keep operations within safe limits.

Safety Considerations

Safety is the top priority in motor control. By following safety rules, you can lower risks during maintenance. Here are some tips:

- Make sure circuits are off before you start.

- Wear the right protective gear, like gloves and goggles.

- Stick to voltage limits to avoid electrical dangers.

When you’re thinking about building your own motor controller, remember that advanced controls like sinusoidal commutation offer smoother operation. But, they also add complexity. It’s often safer and more cost-effective to buy pre-built solutions from trusted brands like Vantec or Roboteq for high-power motors. This approach reduces safety risks and makes maintenance easier. For more on signal modulation and circuit design, check out this resource.

Future Trends in Motor Control with Transistors

The future of motor control technology looks bright. We’re seeing big steps forward in making things more efficient and precise. This is thanks to advancements in semiconductor technology, especially with Smart IC technology. These changes will shape the future of motor control in many industries.

Advances in Semiconductor Technology

New developments in semiconductors have made transistors smaller and more powerful. These semiconductor technology advancements allow for simpler designs. They pack more functions into one package, cutting down on parts needed.

This makes motor control systems more efficient. It boosts performance and saves energy in fields like robotics, cars, and industrial automation.

Predictions for the Industry

The future might bring AI-powered motor control systems. This could make things even more adaptable and efficient. Experts think we’ll see more high-performance BLDC motors replacing older types.

As we need better and more reliable solutions, Smart IC technology will be key. We can expect new control algorithms that adjust motor performance on the fly. This will lead to better efficiency and less energy use.

Resources for Further Learning

For those looking to learn more about motor speed control, many resources are available. Reading books and articles on motor control theory can be very helpful. These materials provide deep insights into how transistors work in motor control.

They are great for both experienced professionals and beginners. These resources are key to understanding motor control systems better.

Recommended Books and Journals

Quality literature can greatly improve your understanding of motor control systems. Books often cover control algorithms and Universal DC motor control principles. They discuss topics like Phase Angle Control and PWM Chopper Control.

Research on BLDC motor control is also important. It covers topics like rotor position knowledge, dead time insertion, and commutation strategies. This knowledge is essential for future projects.

Online Courses and Tutorials

Many online platforms offer courses to improve your motor control skills. These courses cover a wide range of topics. They include practical speed control techniques and hands-on projects.

For example, the Kitronik Inventor’s Kit for the BBC micro:bit costs £21.00. The BBC micro:bit Starter Kit is £12.85. These courses focus on real-world applications, making learning more engaging.